Why choose the Hydraulic System

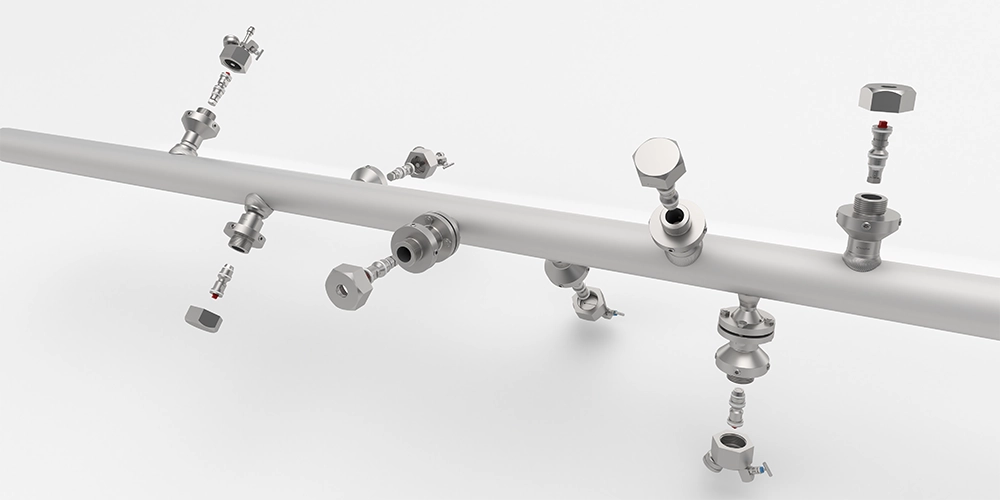

The Hydraulic Access System and Hydraulic Retrieval Kit allows for installation and retrieval of Corrosion Probes, Weight Loss Coupons Assemblies under full operational pressure being the safest and most reliable system.

The high-quality design and construction of the system, as well as its inherent operating principle (hydraulic), have all contributed vastly to placing the hydraulic access and retrieval system as the preferred “Access under Pressure” system of today.

The system has important advantages from an operational and a safety point of view, and is therefore specified by an increasing number of company’s worldwide for new installations. Many companies also convert from traditional mechanical access systems to the Hydraulic System, using Hydraulic Access Fitting Adapters.

The Hydraulic Retriever Kit includes two main components, a Hydraulic Retriever and a hydraulic pump with hoses and other accessories. The Service Valve Kit comes in single or double isolation versions; the double isolation service valve with two balls improves the safety in sour service.

The advantages and benefits of the Hydraulic system

1. Small Size and Light Weight

The hydraulic working concept of the Hydraulic Retrieval system results in a much smaller and lighter (compact) Retriever Tool than traditional mechanical tools. The hydraulic retriever is approximately half the length and weight of traditional mechanical tools.

2. No Threaded Connection

The traditional mechanical access fittings use of a threaded connection between the plug and fitting can result in stuck plugs, caused by corrosion and/or a galling problem which can occur when water and solid particles are present in the flow. The Hydraulic System has no threaded connection between the plug and access fitting, hence galling problems and stuck plugs are avoided. Four locking pins hold the internal plug in position during retrieval operations.

3. Operational Safety

The Hydraulic Retriever has no external moving parts and is therefore safer in operation than the traditional mechanical retriever. Traditional tools require manual rotation of the outer barrel and of the threaded plug during the insertion and removal process. This procedure can cause serious accidents if the pressure is not properly balanced in the retrieval tool during operation.

4. Safety of Personnel

The Hydraulic Retriever is always operated from a distance (typically 2 3 metres) away from the high-pressure point (access fitting) via a hydraulically operated system of hoses and pneumatically operated pump, minimising the risk of exposure to operators. The traditional mechanical retriever requires the operator to manually operate the cylinder during the entire retrieval process.

5. Accessibility

The Hydraulic Retriever’s small size, short length and light weight provides easy handling and greater flexibility, enabling it to be used in positions which would otherwise not be accessed by a traditional mechanical retriever.

6. Simplicity and Ease of Operation

The simplicity of the Hydraulic Retriever, in addition to its compactness and light weight, provides easy operation.

7. Ease of Alignment

Equipment requiring precise alignment in the access fitting pressurised system is a simple and straight forward task with the Hydraulic Retriever, and does not require special skills or training of the operator. However, the accurate and proper alignment of probes/coupons utilising the traditional retriever relies on the hand of an experienced operator.

8. Efficiency

The Hydraulic Retrieval system provides a retrieval system preferred by field technicians and engineers due to its safety features, ease of use, lightweight and small size. This gives the technicians full confidence in handling of the equipment, knowing that the high-risk task of retrieving probes/coupons under pressure can be done in a safe and secure manner every time.

9. Environmentally Friendly

Less than half the discharge of traditional systems, improved safety in sour service.

Hydraulic adapters can be provided to convert the existing two-inch mechanical system into 2-inch hydraulic system for a safer and more reliable operation, such converting can be done without having a shutdown.

Explore Hydraulic system products and Hydraulic Retrieval kit.