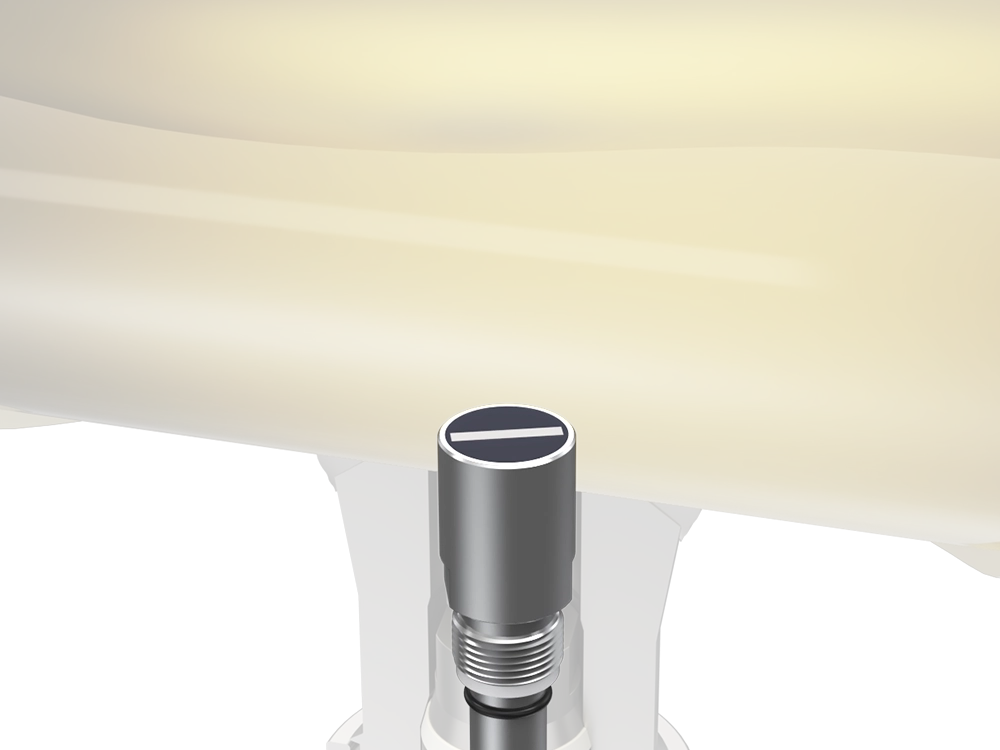

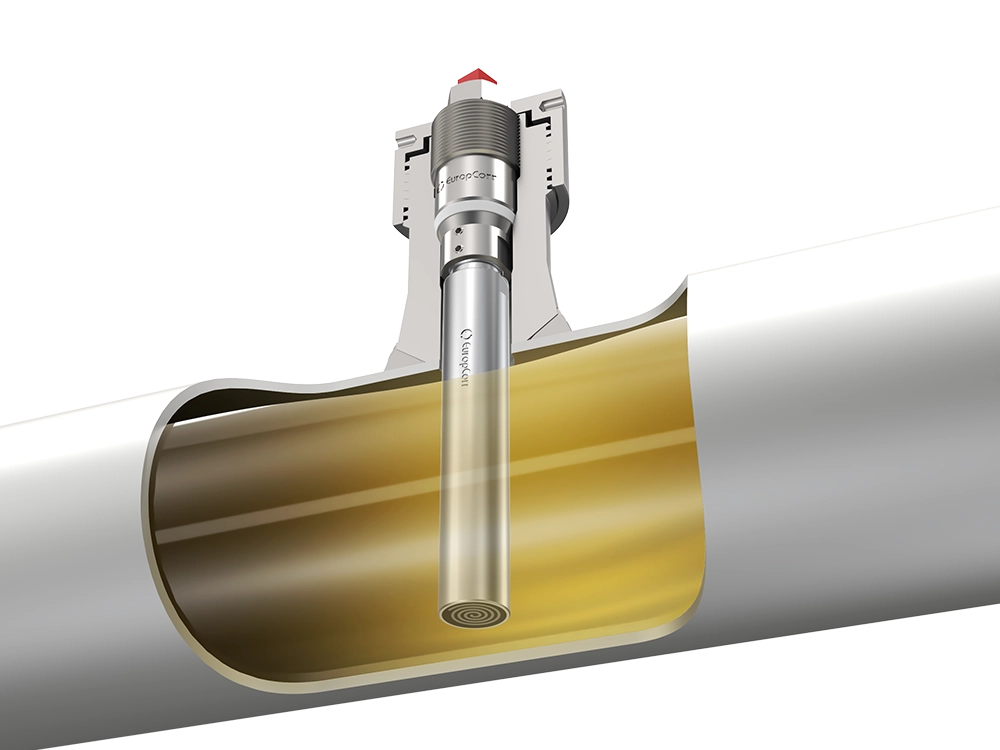

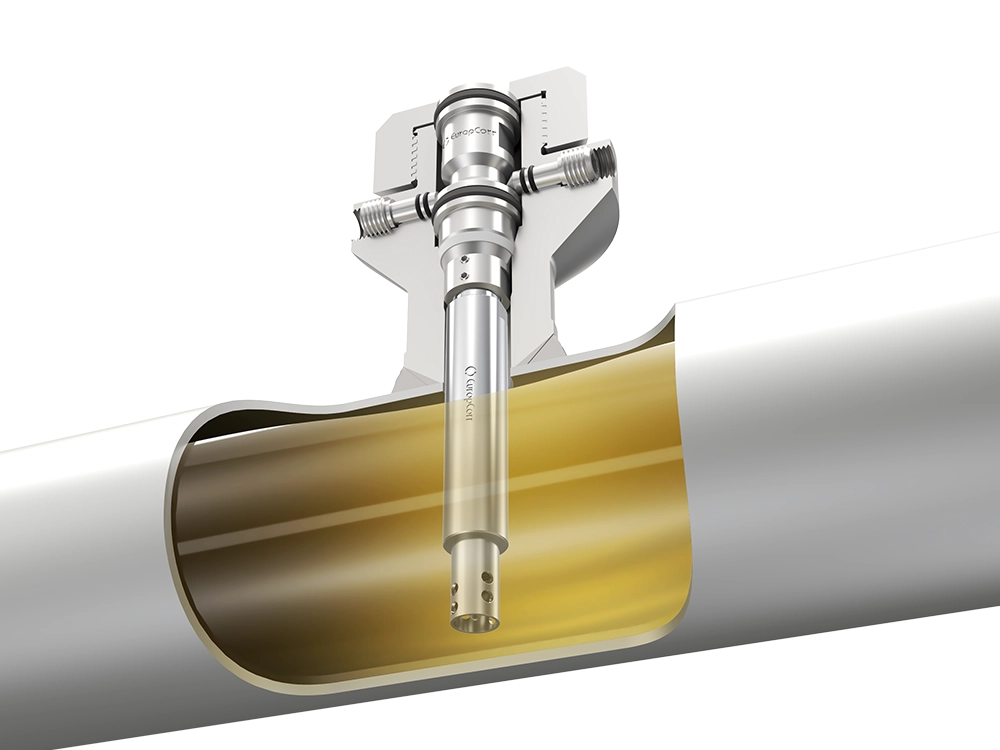

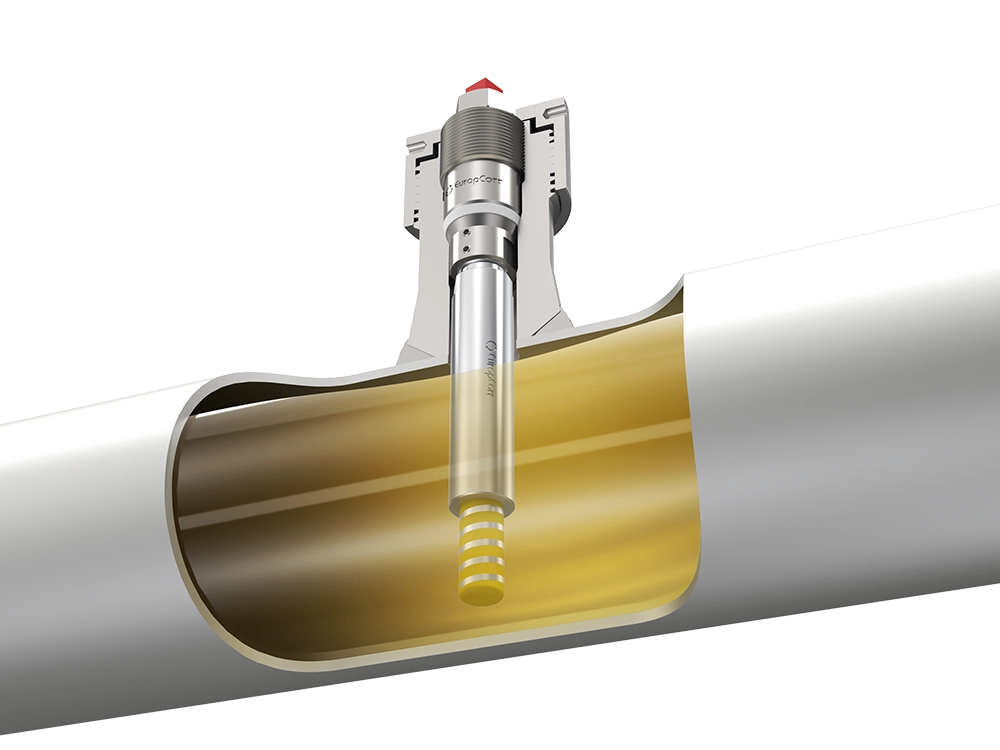

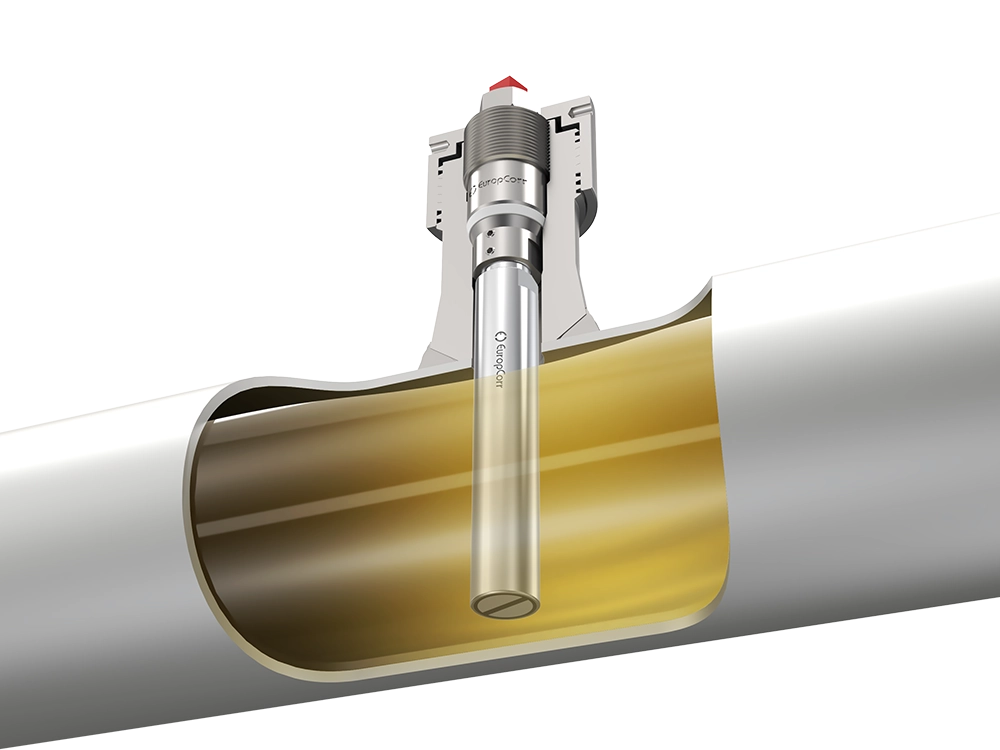

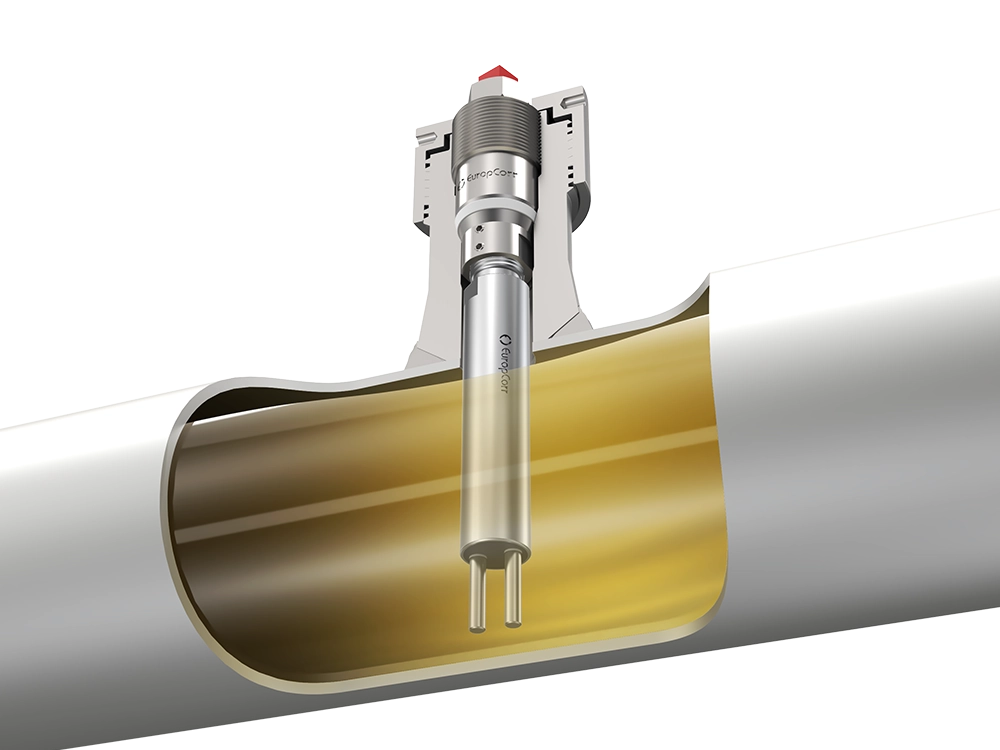

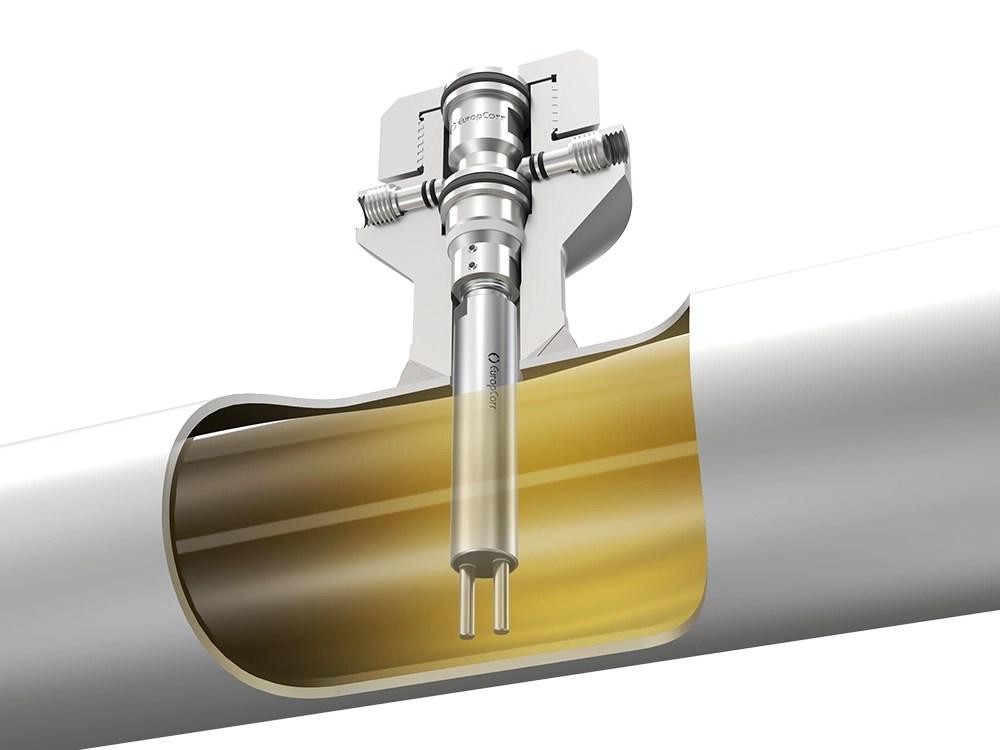

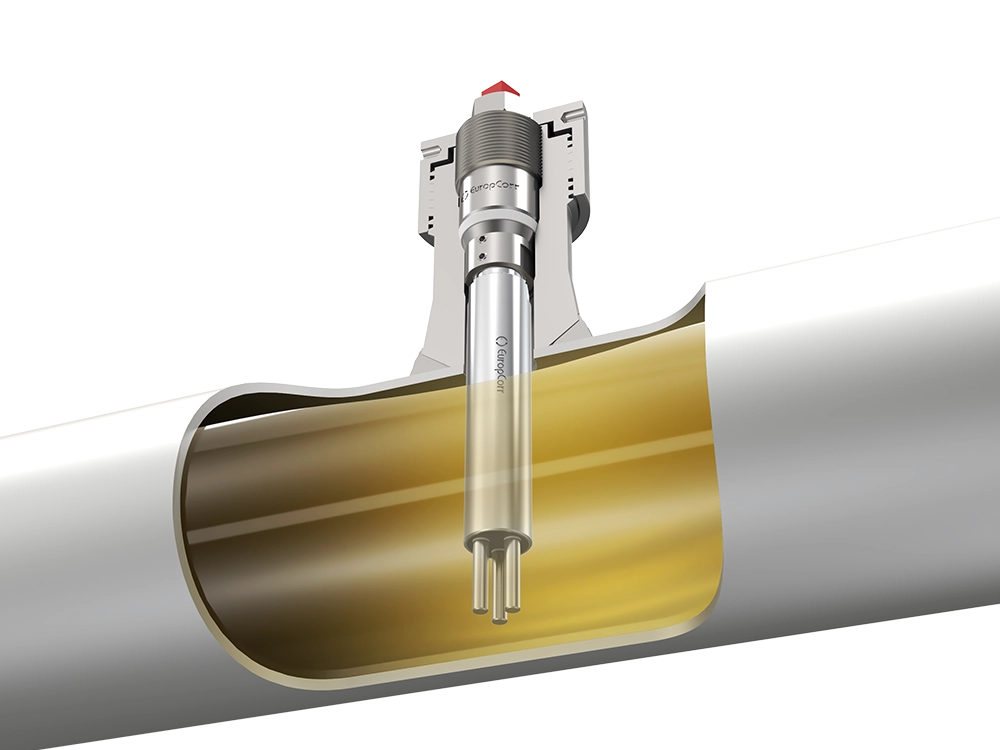

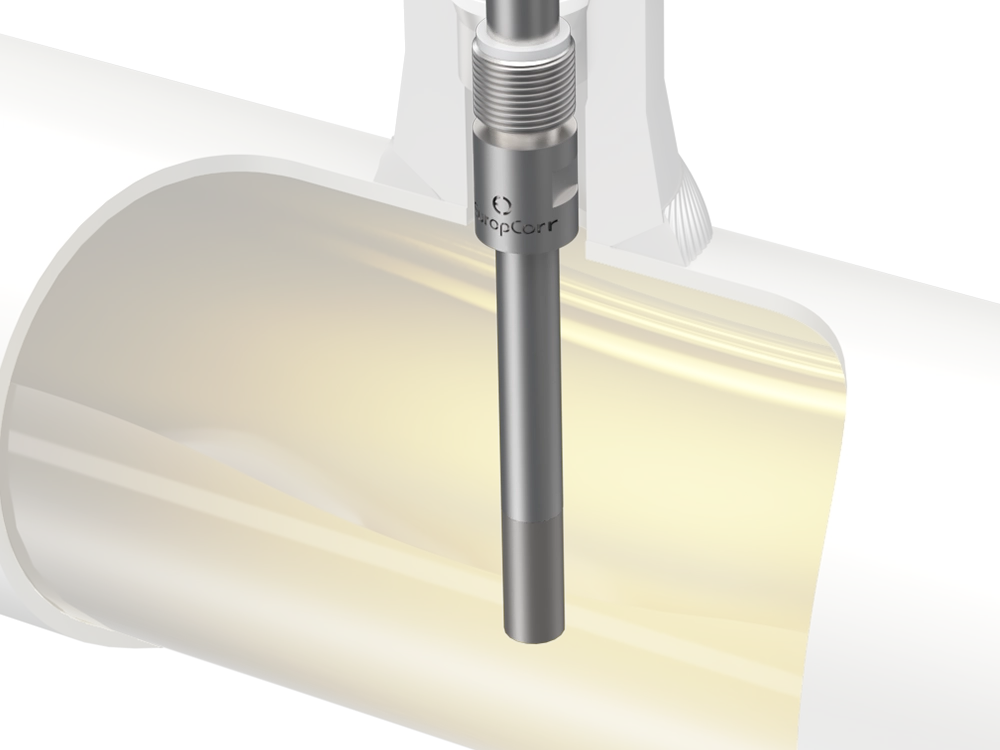

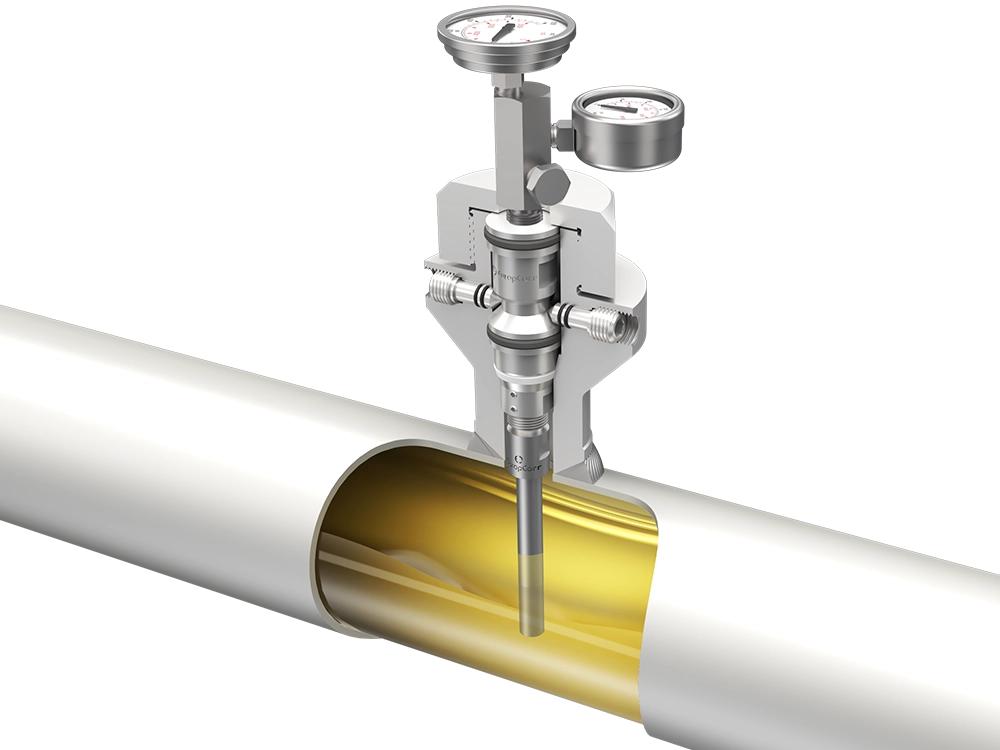

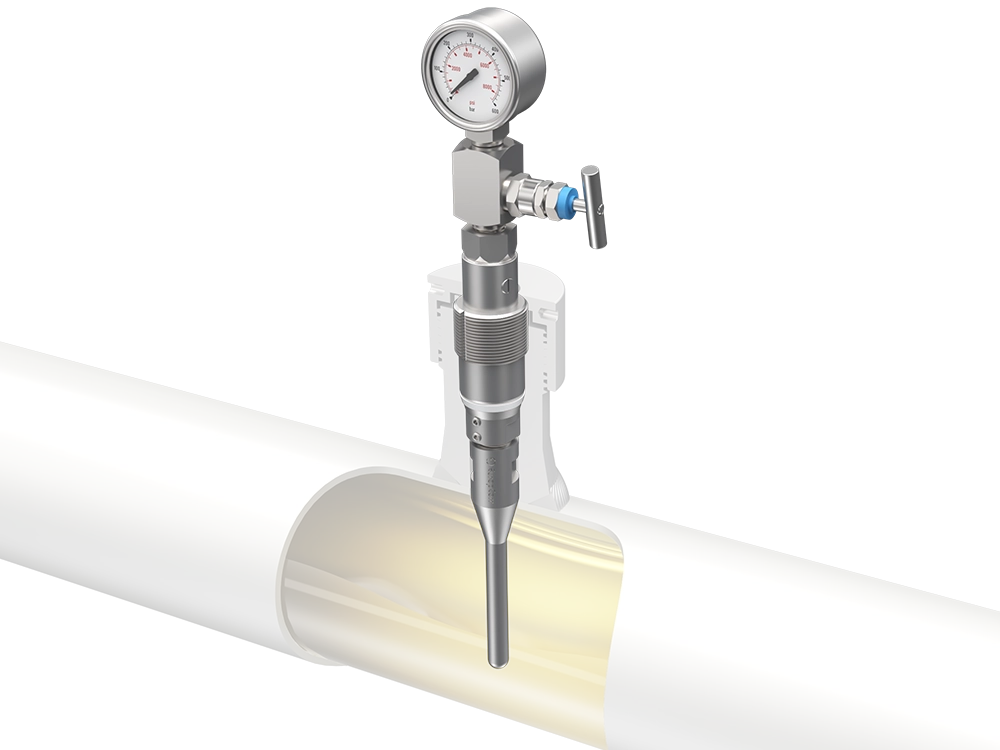

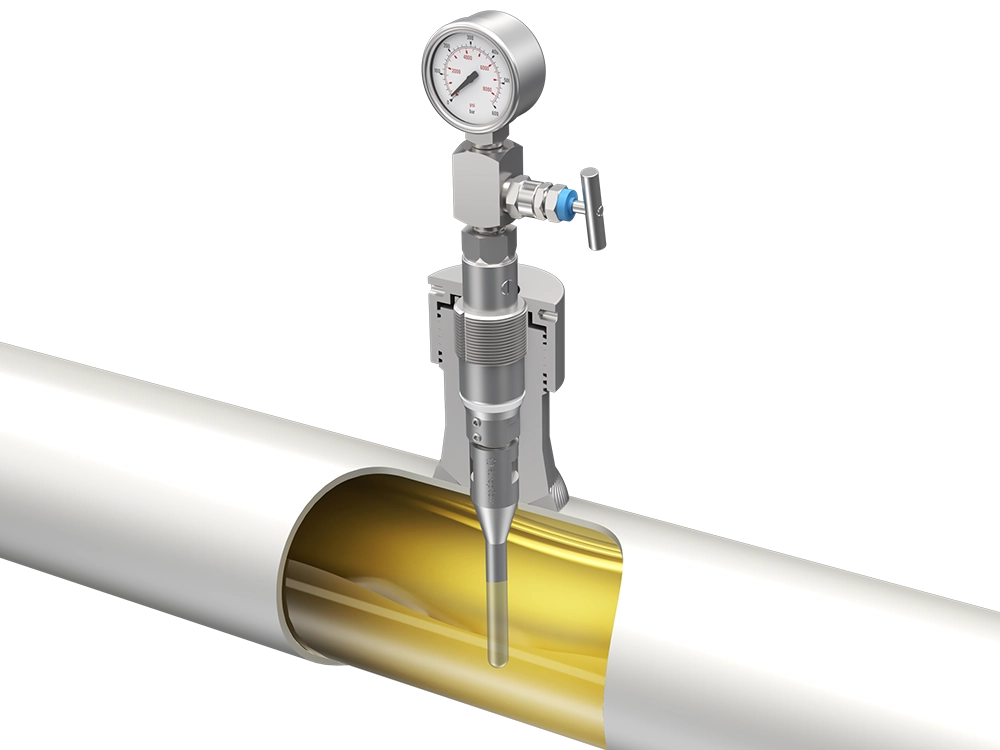

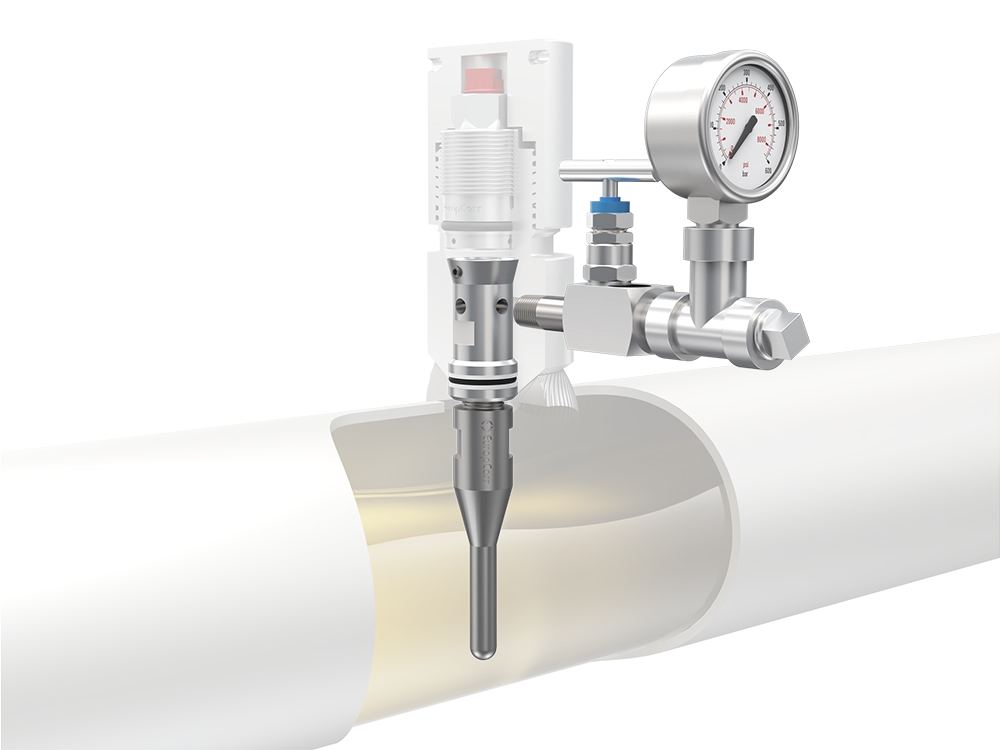

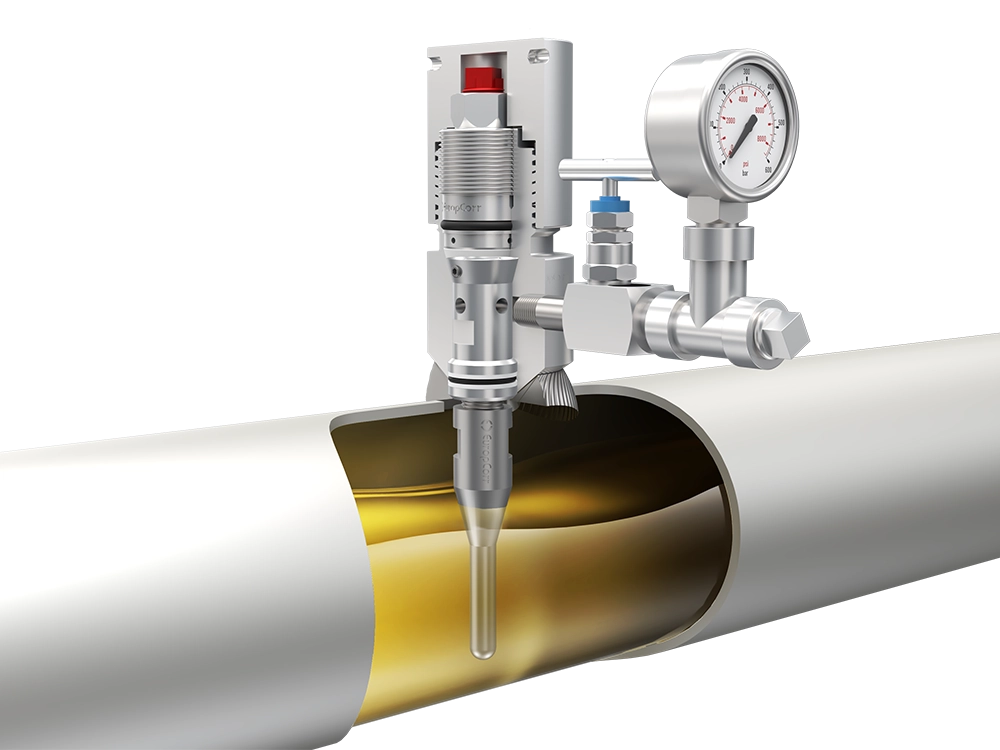

The Probes are designed to facilitate the measurement of corrosion without removing the monitoring device from service, allowing continuous and direct readings.

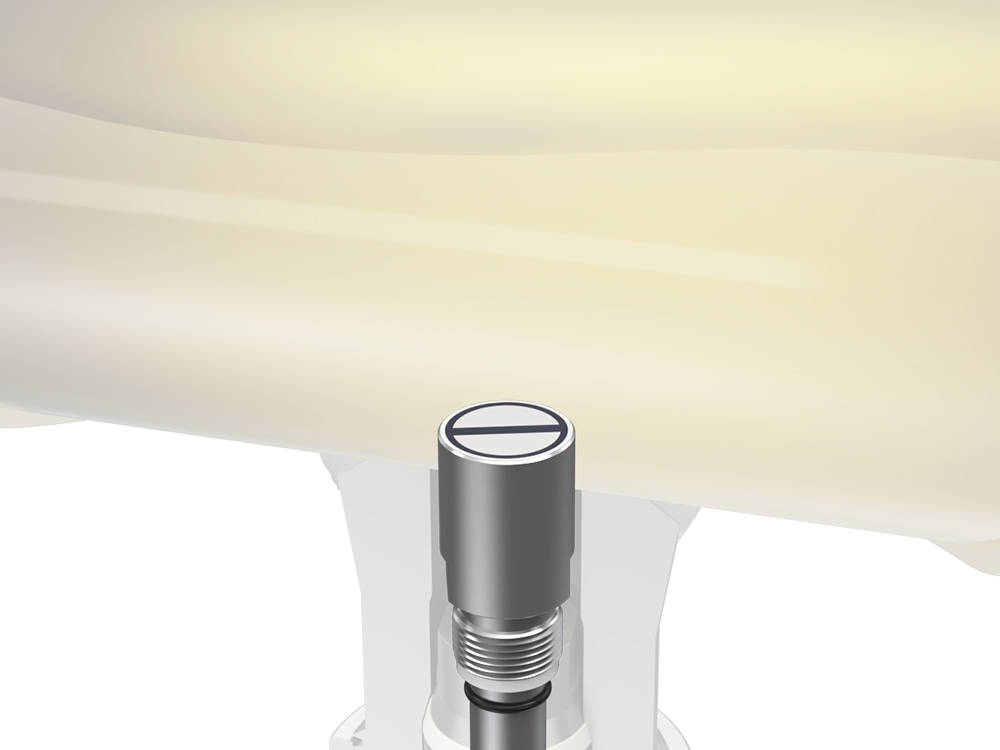

ER Probes

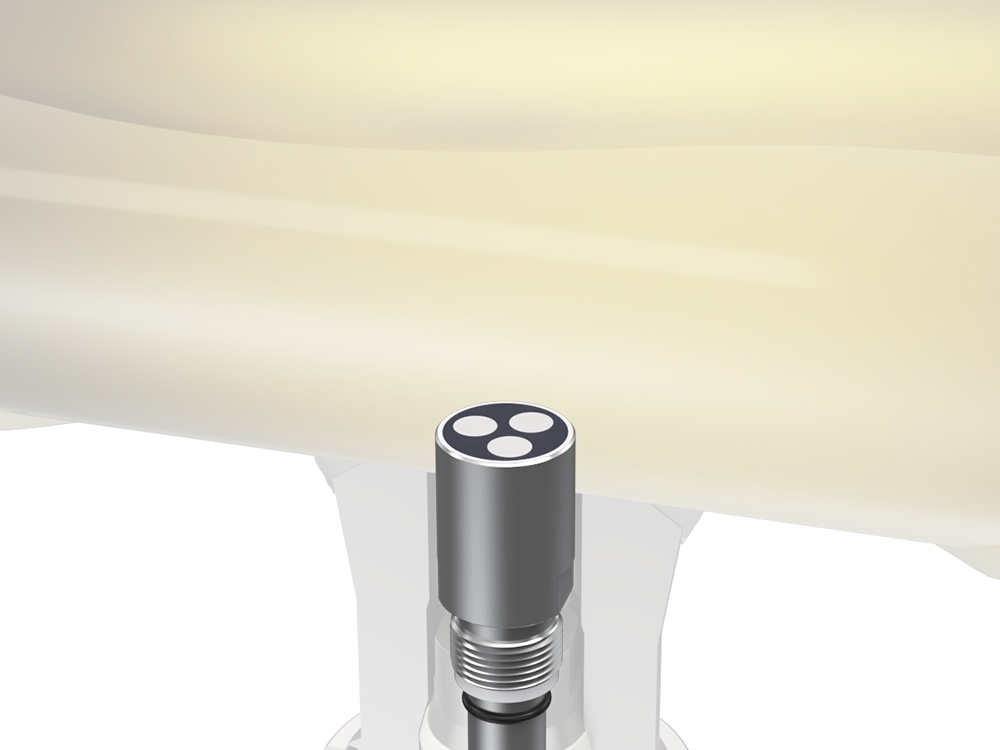

LPR Probes

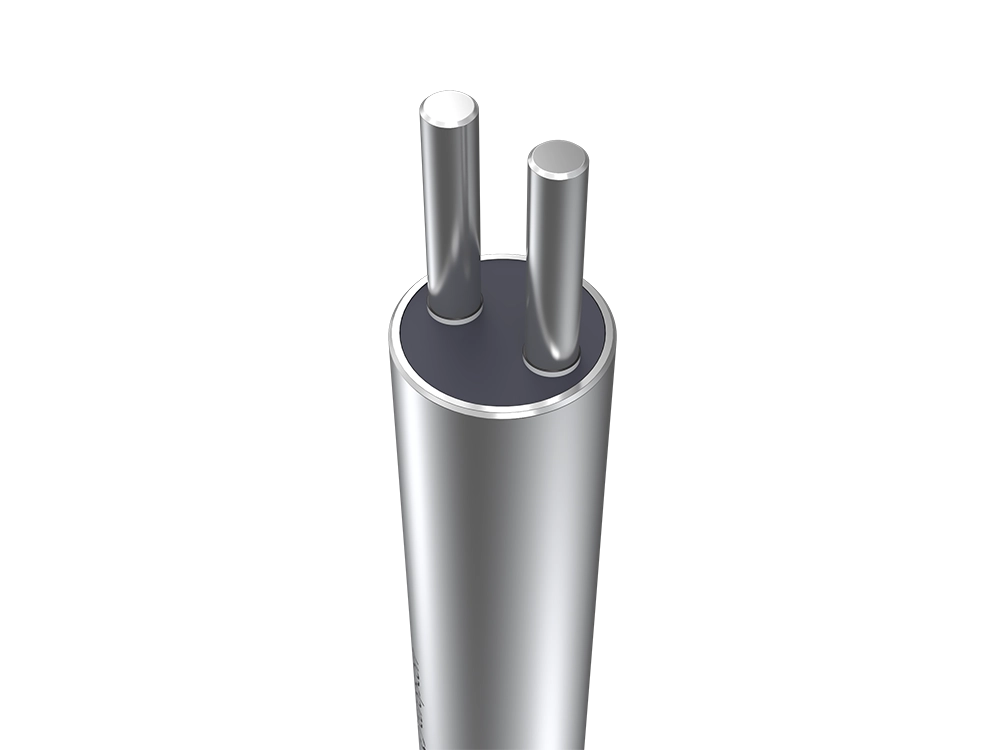

Hydrogen Probes

Sand Probes

Probes - Corrosion, Erosion & Hydrogen

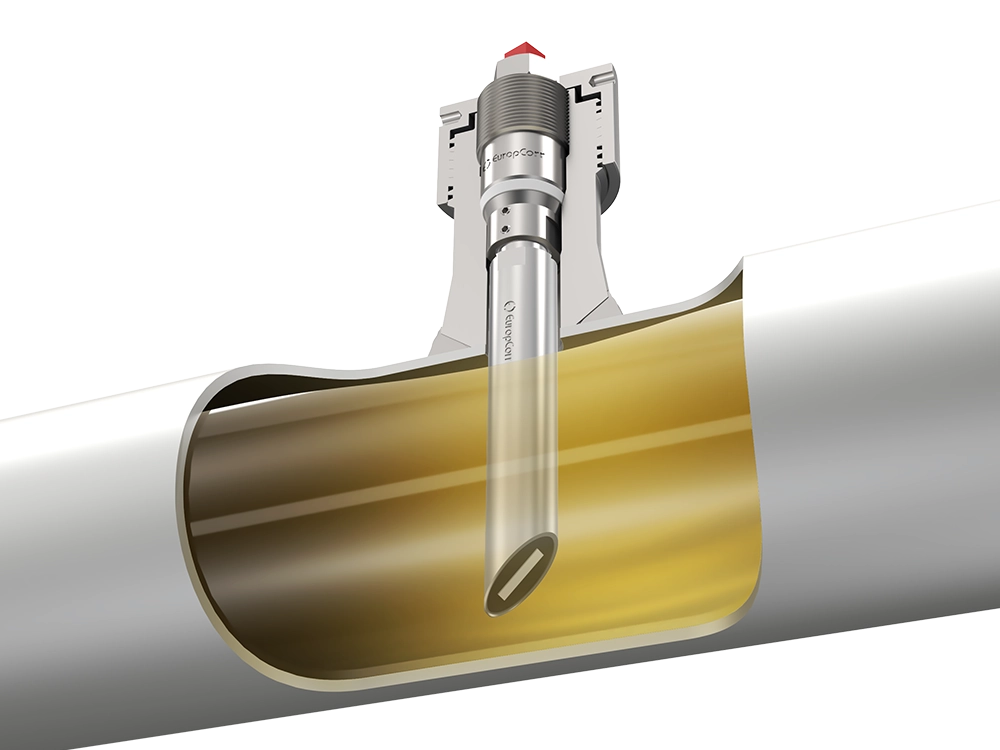

The Probes are designed to study corrosion, erosion and other phenomena that influence pipelines and vessels. Compared to traditional Coupons, this monitoring method facilitates continuous corrosion measurement without having to remove the monitoring device from service.

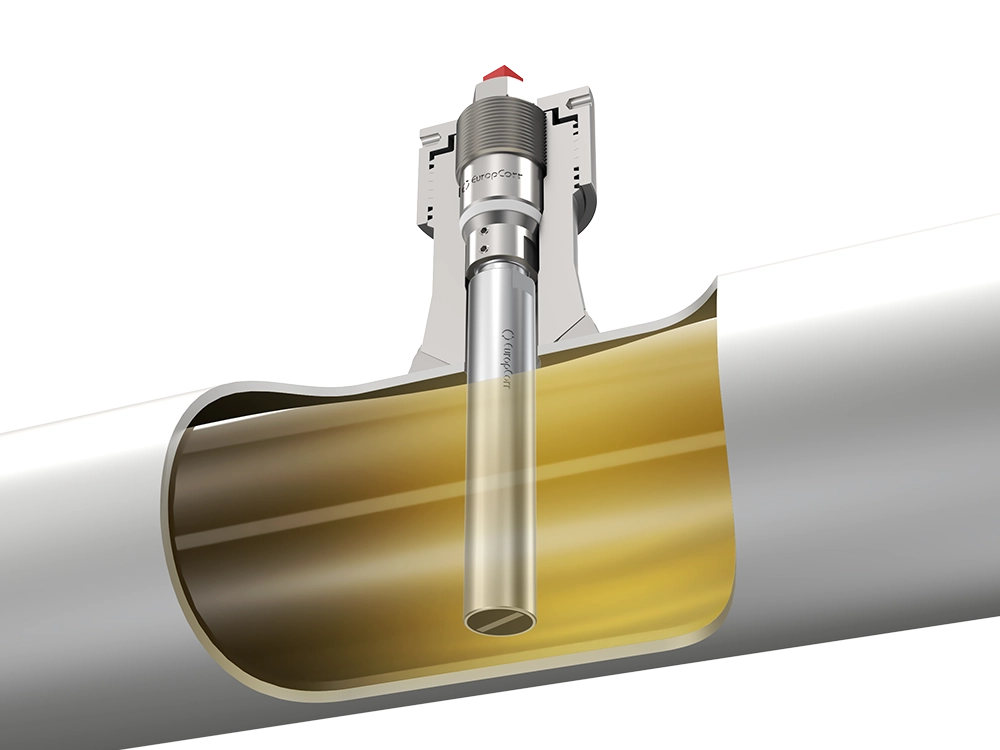

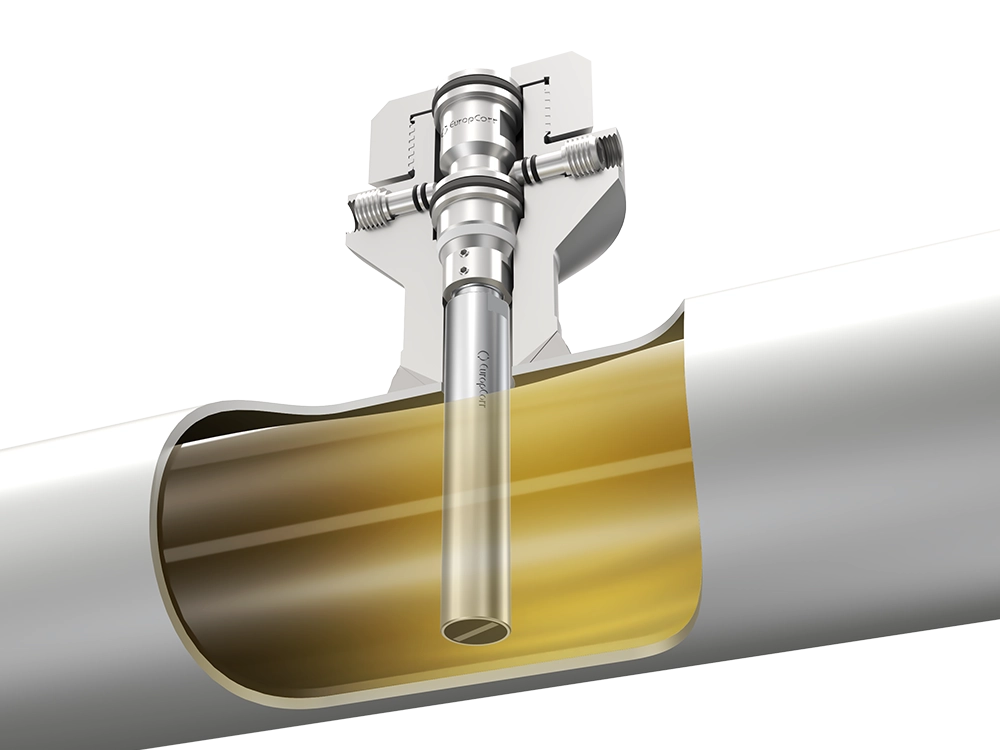

At a technological level we can divide them into two groups:

– Of Electronic type that generates digital data and therefore downloaded through instruments.

– Or analog type, which are connected to traditional sensors, such as a pressure gauge or a thermometer, which allow us to see the effect of corrosion directly.

For different monitoring purposes, we have a variety of probes:

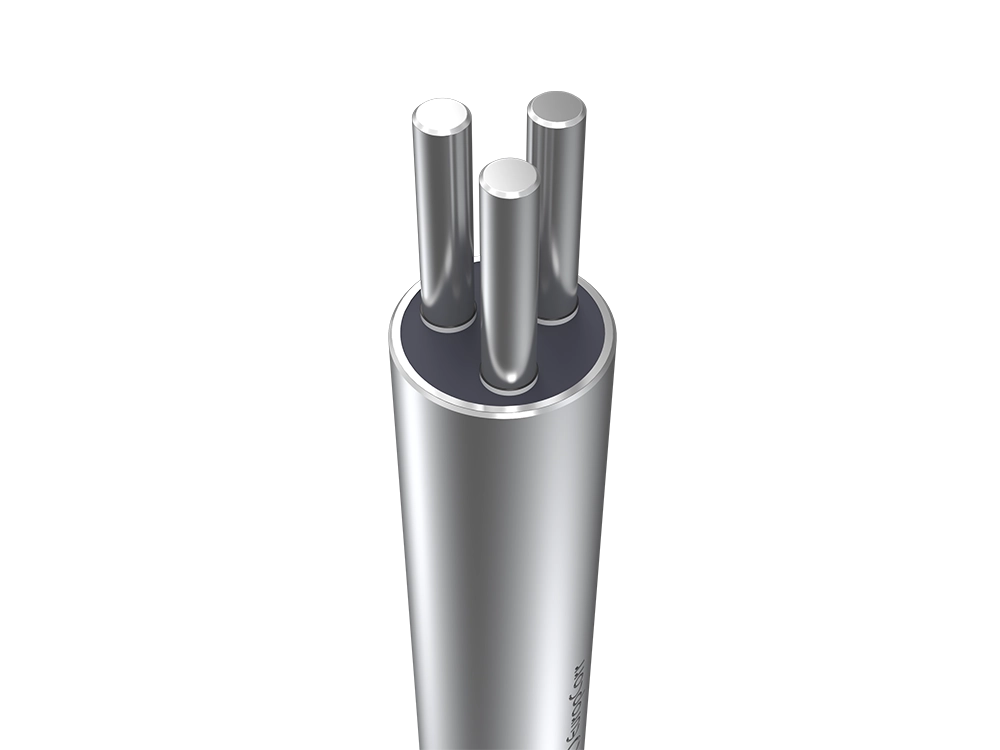

– ER Probes are used to measure instantaneous metal loss and corrosion rate on time.

– LPR Probes provide instantaneous corrosion rate in waterbased environments.

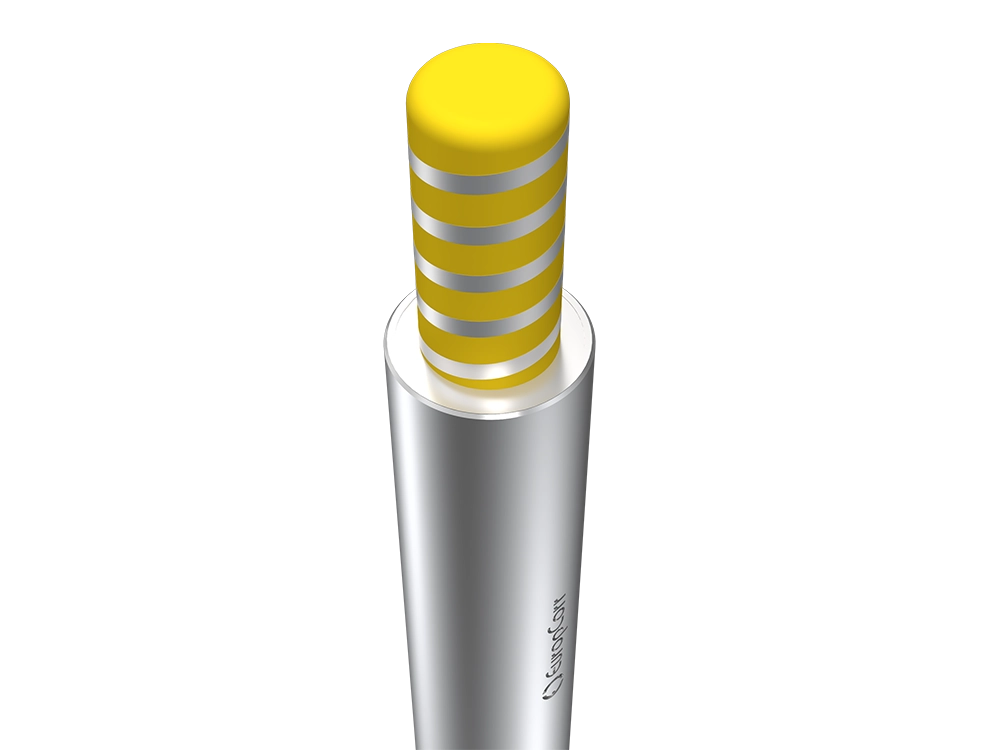

– Erosion Sand Probes provide early detection of sand erosion.

– Hydrogen Probes are used to monitor hydrogen that has permeated into the steel in an acidic environment.